The Evolution of Tire Technology

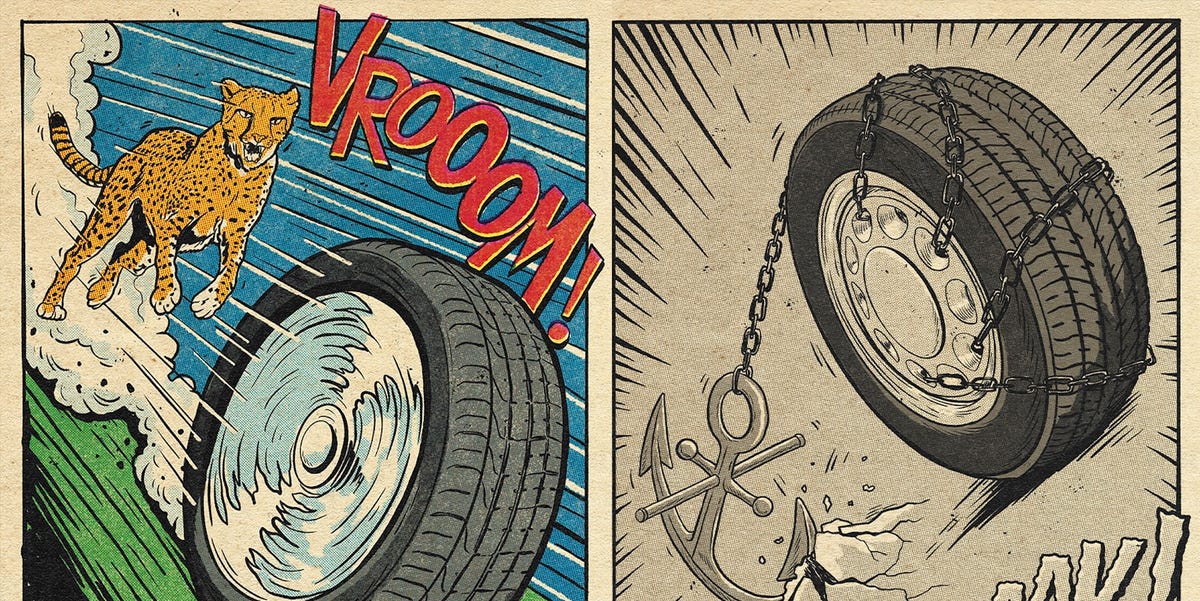

Tires have undergone significant advancements over the past few decades, to the extent that replacing them can dramatically enhance a vehicle's performance. In 2024, the new Michelin Pilot Sport Cup 2 tires, specifically designed for the Porsche Carrera GT, contributed to shaving more than 15 seconds off the car’s Nürburgring lap time compared to its 2004 setting. This kind of improvement highlights the intricate science behind tire development.

Tires are far more complex than they appear, with over 100 different components involved in their construction. These elements, often down to the molecular level, have made tires faster and more resilient across various environmental conditions.

Key Components of Modern Tires

Tire components can be categorized into several broad groups. The most noticeable is rubber, which consists of elastomers derived from natural or synthetic sources, such as trees or petroleum byproducts. Structural reinforcements, like steel or textile cords, provide additional strength. Fillers, including carbon black and silica, enhance durability and grip. Additives such as resins, oils, and curing agents play essential roles in the tire's overall performance.

Exploring every aspect in detail would require multiple issues of Road & Track. Therefore, this discussion focuses on the most significant contributors to recent tire advancements.

Innovations in Elastomer Technology

One of the most notable changes came from the introduction of functionalized elastomers over a decade ago. This innovation allows tire chemists to customize certain characteristics of the rubber, which was previously considered impossible. According to Cyrille Roget, scientific and innovation communication director for the Michelin Group, these modifications have transformed adherence, energy efficiency, and wear performance.

Ian Coke, chief technical officer for Pirelli North America, also highlights recent developments in elastomer technology. He notes that Pirelli can now use specialized compositions tailored to specific applications, whether for summer, winter, all-season, or motorsport tires.

Material and Design Advancements

In addition to elastomers, the evolution of tires has been driven by new materials and development methods. High-tenacity aramid and hybrid cords, along with bead technologies that improve rim adherence, contribute to better precision and control. The physical design of tires also plays a crucial role. For example, the wavy, corrugated shape of the steel belts on the Pilot Sport 4S enhances tread stability.

New high-tensile-steel cords have allowed for reductions in weight and rolling resistance, improving energy efficiency. Structural improvements give tire engineers more precise control over the contact patch, reducing heat-induced flex and wear.

Production Equipment and Digital Tools

Production equipment has also seen significant advancements. Michelin and other tire companies have used 3-D-printed molds to introduce complex tread shapes and voids. New sipe designs reduce deformation, improving dry performance. As tires wear, additional tread grooves can develop at lower tread depths, extending their lifespan.

Digital tools have played a critical role in accelerating tire development. Simulation software used in motorsport, such as Formula 1, WEC, and IMSA, has transitioned to the production of street-car tires. This allows engineers to build tires virtually and optimize their contact patch and construction.

The pressure to perform in racing has led to innovations like improved asymmetric sidewall stiffness, belt angles, and cap plies, which have migrated to the consumer market. Michelin’s TameTire modeling software simulates a tire’s performance as it is driven, integrating into full vehicle simulations used by both racing outfits and auto manufacturers.

Virtual Modeling and AI Integration

Coke emphasizes that virtual-modeling tools used in F1 have enabled faster and more precise development cycles in Pirelli’s street tires. The latest generation of the P Zero, for instance, was engineered using advanced artificial-intelligence algorithms and virtual prototyping. This allows engineers to predict tire behavior in a wide range of conditions before physical testing.

These technologies, combined with improved manufacturing precision, tread-pattern optimization, and low-rolling-resistance compounds, now enable high-performance road tires to match or even exceed the capabilities of supercar tires from two or three decades ago. They deliver superior grip, efficiency, and safety.

Conclusion

There is no secret sauce to making tires faster, and this remains true today as when the Carrera GT was first introduced. Instead, there has been incremental progress in every aspect of building a tire, leading to overall improvements that result in drastically faster lap times.

0 comments:

Ikutan Komentar